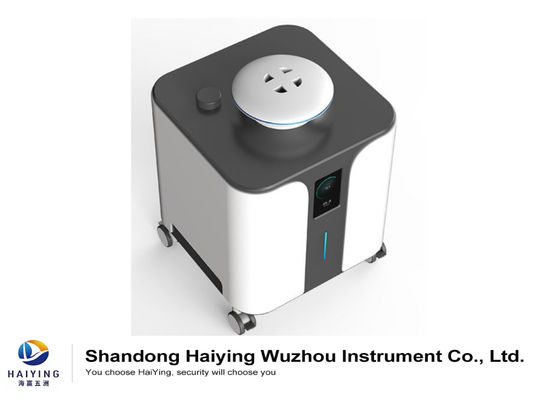

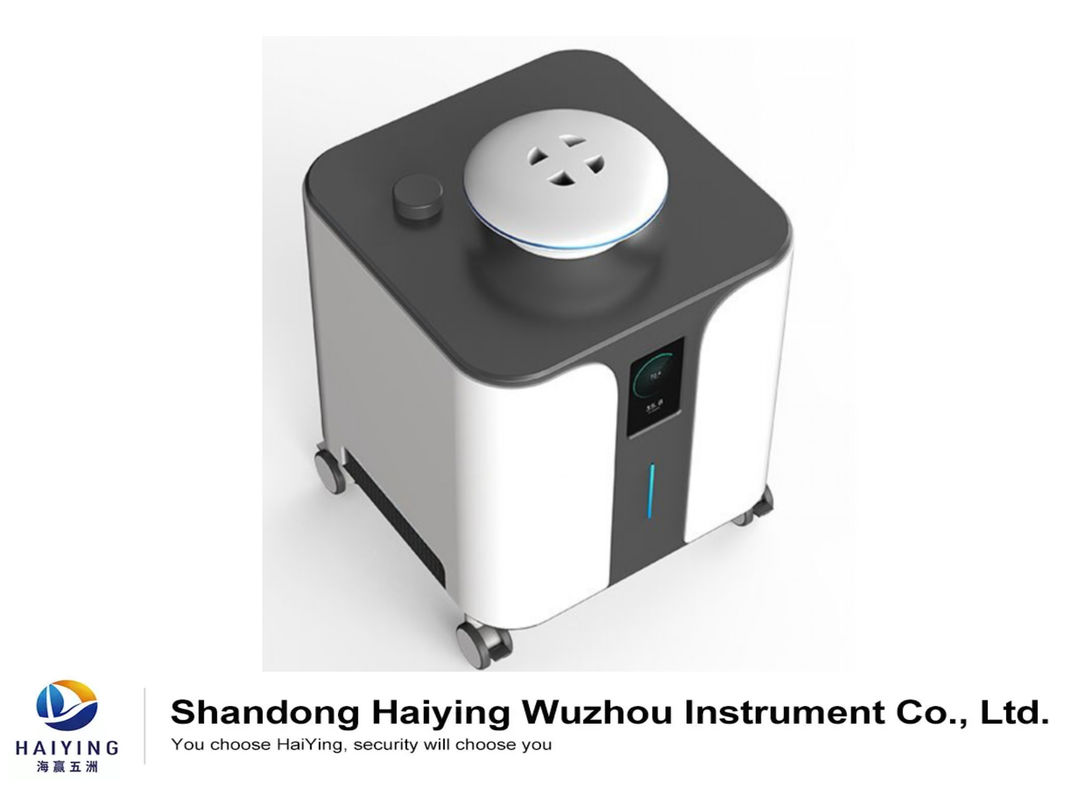

Class II Hydrogen Peroxide Sterilizer

Product Details:

| Place of Origin: | China |

| Brand Name: | HAIYING |

| Certification: | CE certificate |

| Model Number: | DS1001/DS1002 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden case |

| Delivery Time: | 5-8 work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 100 sets/7days |

|

Detail Information |

|||

| Tybe: | Hydrogen Peroxide Sterilizer | Model: | DS1001/DS1002 |

|---|---|---|---|

| Instrument Classification: | Class II | Warranty: | 1 Year |

| Net Weight: | 48.0 Kg | Length*Width*Depth: | 580mm*580mm*760mm |

| Relative Humidity: | 20-70% | Input Power: | 1100 W |

| Highlight: | Class II Hydrogen Peroxide Sterilizer,DS1001 air sterilizer machine,HAIYING 60Hz Hydrogen Peroxide Sterilizer |

||

Product Description

The disinfection robot uses the robot as a carrier to carry out air atomization and disinfection in the form of diluted disinfectant. According to actual needs, it independently plans the disinfection route, fully automatic indoor unmanned driving, and can perform 360° Dead corner disinfection, 1000m³ space can be disinfected in 15 minutes to avoid the risk of personnel infection.

| Model | DS1001 |

| Input power | 1100W |

| Frequency | 50-60Hz |

| Relative humidity | 20-70% |

Hydrogen Peroxide Sterilizer characteristics:

◆ innovative use of low temperature and low concentration of nano (room temperature) - vaporization separation technology of hydrogen peroxide (LCVHP), to ensure that the hydrogen peroxide vaporizing decomposition;

◆ The use of low concentration of hydrogen peroxide and reduce the corrosion resistance;

◆ pretty or smaller particle size and the bacteria (nm), only for existing high temperature vaporization (flash) hydrogen peroxide (VHP) technology of one over ten or less.

◆ with high temperature and evaporation and spray hydrogen peroxide hydrogen peroxide technology compared to the formation of hydrogen peroxide after particles can be suspended in the air for a long time for Brownian motion without rules, to ensure that the penetration and the sterilization effect of complex region;

◆ due to the formation of hydrogen peroxide particle dry, after the contact surface will produce rebound effect, not like a big wet particles would condense together to form liquid membrane or droplets, no corrosive to choi steel and epoxy floor;

◆ by means of biological indicator bacillus subtilis (BIs) black and fat thermophilic bacillus validation, killing rate could reach 10;

◆ some models equipped with hydrogen peroxide and its residual concentration testing equipment, in full compliance with GMP validation requirements;

◆ with a time program controller or PLC model options (part), to ensure that every day according to the set of programs for clean room disinfection sterilization, no operating personnel present;

◆ is equipped with a speed regulation system and solvent control system, ensure the vaporization of hydrogen peroxide speed according to the need to adjust or control;

◆ equipped with air purification system, to avoid the adverse environment cancellation poison pollution;

◆ without external gas source, an exclusive patent nozzle, and is equipped with solvent filtration, without the risk of clogging nozzle;

The entire sterilization process is divided into four stages:

Preparation stage: the temperature of the steam generating device is raised to a stable condition;

Jet stage: hydrogen peroxide vapor quickly enters the sterilization space (through flash evaporation);

Maintenance stage: the saturated concentration of hydrogen peroxide vapor is kept in the sterilization space; Structural materials

Ventilation stage: hydrogen peroxide vapor decomposes into water vapor and oxygen on the catalyst

![]()